Products > APR Drill Stem Testing Tools

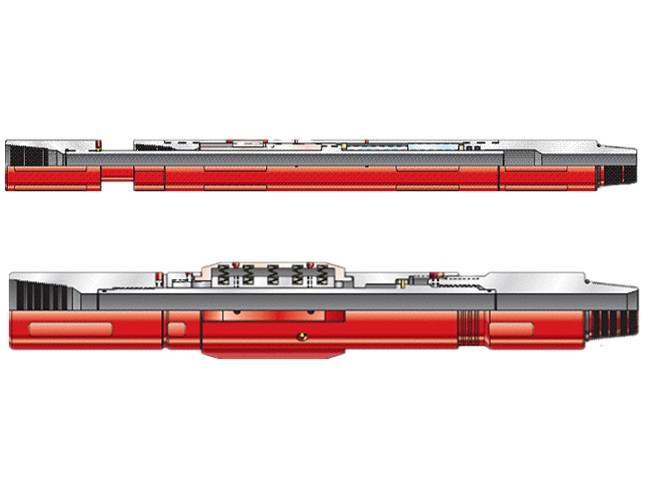

LPR-N TEST VALVE

1. Product Introduction:

This valve is a kind of cased well inside the use of drift diameter annulus pressure operation of the downhole testing switch valve, and its operation through the ground annulus applied operating pressure to complete, ball valve maximum open differential pressure as high as 35 MPa, with multiple switch well ability.

2. Technical Parameters:

| SPECIFICATION | 3 7/8″ | 5″ |

| O.D | 99mm | 127.5mm |

| I.D | 45mm | 57mm |

| LENGTH | 5163mm | 4940mm |

| WORKING PRESSURE | 70MPa | 105MPa |

| WORKING TEMPERATURE | -29℃~+177℃ | -29℃~+177℃ |

| TENSILE STRENGTH | 1479KN | 2377KN |

| BURST STRENGTH | 135MPa | 148MPa |

| COLLAPSE RESISTANCE | 126MPa | 138MPa |

| TORQUE STRENGTH | 34KN•m | 37.1KN•m |

| CONNECTION TYPE | 2 7/8″CAS & 2 7/8″EUE | 3 7/8″CAS & 3 1/2″IF |

OMNI VALVE

1. Product Introduction:

This valve is a kind of the annulus pressure control can realize multiple switch of circulating valve, applicable to cased hole of the full size formation test tubing transmission perforation and full-size test group and operation of pipe string of pressure testing and cycle operation.

2. Technical Parameters:

| SPECIFICATION | 3 7/8″ | 5″ |

| O.D | 99mm | 127.5mm |

| I.D | 45mm | 57mm |

| LENGTH | 6092mm | 6555mm |

| WORKING PRESSURE | 70MPa | 70MPa |

| WORKING TEMPERATURE | -29℃~+177℃ | -29℃~+177℃ |

| TENSILE STRENGTH | 820KN | 1600KN |

| BURST STRENGTH | 135MPa | 148MPa |

| COLLAPSE RESISTANCE | 126MPa | 138MPa |

| OPEN AREA OF CIRCULATION PORT | 1526mm | 2280mm |

| TORQUE STRENGTH | 15KN•m | 30KN•m |

| CONNECTION TYPE | 2 7/8″CAS & 2 7/8″EUE | 3 7/8″CAS & 3 1/2″IF |

RD SAMPLER

1. Product Introduction:

RD sampler is a kind of using in cased well inside by annulus pressure operation full bore sampler. Which mainly used in full size formation test assignments, for downhole pressure state of the formation fluid samples, sample before and after the test tube string are keep full size state, do not affect the subsequent work on.

2. Technical Parameters:

| SPECIFICATION | 3 7/8″ | 5″ |

| O.D | 99mm | 127.5mm |

| I.D | 45mm | 57mm |

| LENGTH | 3055mm | 2198mm |

| WORKING PRESSURE | 70MPa | 70MPa |

| WORKING TEMPERATURE | -29℃~+177℃ | -29℃~+177℃ |

| TENSILE STRENGTH | 1500KN | 2766KN |

| BURST STRENGTH | 130MPa | 95MPa |

| COLLAPSE RESISTANCE | 94MPa | 86MPa |

| TORQUE STRENGTH | 19.5KN•m | 56KN•m |

| CONNECTION TYPE | 2 7/8″CAS & 2 7/8″EUE | 3 7/8″CAS & 3 1/2″IF |

RD SAFETY CIRCULATING VALVE

1. Product Introduction:

This valve is mainly used to seal grease traps gas at the end of the formation test cycle operations, while the valve between the ball valve and test valve, ball valve can trap the period of formation fluid samples. Downhole operation, the valve is open will not be closed again. As the safety valve, can be in any of the test period at a time to operate the tool to seal testing string, if the four cycles of the valve hole is blocked, can be used as a disposable shut-in valve.

2. Technical Parameters:

| SPECIFICATION | 3 7/8″ | 5″ |

| OD | 99mm | 127.5mm |

| ID | 45mm | 57mm |

| LENGTH | 1883mm | 1847mm |

| WORKING PRESSURE | 70MPa | 70MPa |

| WORKING TEMPERATURE | -29℃~+177℃ | -29℃~+177℃ |

| TENSILE STRENGTH | 1147KN | 2430KN |

| BURST STRENGTH | 107MPa | 132MPa |

| COLLAPSE RESISTANCE | 90MPa | 123MPa |

| TORQUE STRENGTH | 12KN•m | 35KN•m |

| CONNECTION TYPE | 2 7/8″CAS & 2 7/8″EUE | 3 7/8″CAS & 3 1/2″IF |

HYDRAULIC CIRCULATING VALVE

1. Product Introduction:

This valve is a full bore cycle tools, it can be connected to the top or bottom of the tester, and then in the bottom of the tester, the hydraulic circulation valve as a packer bypass can reduce tool from the drilling, downhole pumping action; when connected to the top of the hydraulic circulation valve is used as a circulating valve test cycle formation fluid accumulated in the column. Delay part of the hydraulic cycle parts of the valve from the cylinder and metering sets and parts by the cycle of the outer tube and the cycle sets the bypass parts.

2. Technical Parameters:

| SPECIFICATION | 3 7/8″ | 5″ |

| O.D | 99mm | 127.5mm |

| I.D | 45mm | 57mm |

| LENGTH | 2643mm | 2322mm |

| WORKING PRESSURE | 70MPa | 70MPa |

| WORKING TEMPERATURE | -29℃~+177℃ | -29℃~+177℃ |

| TENSILE STRENGTH | 850KN | 1193KN |

| BURST STRENGTH | 170MPa | 111.5MPa |

| COLLAPSE RESISTANCE | 157MPa | 103.4MPa |

| TORQUE STRENGTH | 15KN•m | 18KN•m |

| CONNECTION TYPE | 2 7/8″CAS & 2 7/8″EUE | 3 7/8″CAS & 3 1/2″IF |

1. Product Introduction:

This tool is mainly used for drilling floating on board full bore formation testing, hanging testing and fracturing, acidizing jobs, compensation drilling pontoons floating up and down to ensure that the sit to put the right amount of gravity on the downhole tools, but also inland formation testing operations, compensation column caused by elongation and contraction due to changes in temperature, pressure, but also connected to the lower end of the test valve of the multi-stream, and to provide free travel for the switching of the test valve.

2. Technical Parameters:

| SPECIFICATION | 3 7/8″ | 5″ |

| O.D | 99mm | 127.5mm |

| I.D | 45mm | 57mm |

| LENGTH | 4688mm | 4688mm |

| STROKE | 1524mm | 1524mm |

| WORKING PRESSURE | 70MPa | 105MPa |

| WORKING TEMPERATURE | -29℃~+177℃ | -29℃~+177℃ |

| TENSILE STRENGTH | 870KN | 1440KN |

| BURST STRENGTH | 105MPa | 147MPa |

| COLLAPSE RESISTANCE | 100MPa | 137MPa |

| TORQUE STRENGTH | 10.5KN•m | 24KN•m |

| CONNECTION TYPE | 2 7/8″CAS & 2 7/8″EUE | 3 7/8″CAS & 3 1/2″IF |

1. Product Introduction:

This tool is a security tool, testing tool string stuck drill available shock first shock column to make it stuck Shock first of a pulling force is applied to the column, and thenwhen the column in the drill pipe is stretched, the tension on the shock suddenly released, the drill pipe contraction, a shock role to shock jammed tools, such as the need to repeatedly shock can be repeated operations, repeat the above procedure to obtain.

2. Technical Parameters:

| SPECIFICATION | 3 7/8″ | 5″ |

| /OD | 99mm | 127.5mm |

| ID | 38mm | 57mm |

| LENGTH | 1574mm | 1708mm |

| STROKE | 255mm | 255mm |

| TENSILE | 177.9KN | 222.2KN |

| WORKING PRESSURE | 70MPa | 70MPa |

| WORKING TEMPERATURE | -29℃~+177℃ | -29℃~+177℃ |

| TENSILE STRENGTH | 1197KN | 1406KN |

| BURST STRENGTH | 135MPa | 118MPa |

| COLLAPSE RESISTANCE | 159MPa | 77MPa |

| TORQUE STRENGTH | 32KN•m | 22KN•m |

| CONNECTION TYPE | 2 7/8″CAS & 2 7/8″EUE | 3 7/8″CAS & 3 1/2″IF |

RTTS PACKER

1. Product Introduction:

RTTS packer is a large diameter, bi-directional pressure packer, mechanical suspension seat seal packer. Design used for the formation testing, acidizing, cementing plug operations, RTTS packer in time to go down to complete a variety of functions operating.

2. Technical Parameters:

| SPECIFICATION | 5″ | 5 1/2″ | 7″ | 9 5/8″ |

| O.D | 103mm | 115.6mm | 151.1mm | 207.8mm |

| I.D | 45mm | 48mm | 61mm | 101mm |

| LENGTH | 1226mm | 1232mm | 1380mm | 2088mm |

| WORKING PRESSURE | 70MPa | 70MPa | 70MPa | 70MPa |

| WORKING TEMPERATURE | -29℃~+177℃ | -29℃~+177℃ | -29℃~+177℃ | -29℃~+177℃ |

| TENSILE STRENGTH | 719KN | 793KN | 905KN | 2519KN |

| BURST STRENGTH | 122MPa | 132MPa | 92MPa | 93MPa |

| COLLAPSE RESISTANCE | 115MPa | 124MPa | 88MPa | 88MPa |

| CONNECTION TYPE |

33/32"-10UN.B ×2 7/8"EUE.P |

3 1/2"-8UN. B×2 7/8"EUE.P | 4 5/32"-8UN. B ×2 7/8"EUE. P | 4 1/2"IF. B ×41/2"IF. P |

RTTS(RTTS SAFETY JOINT)

1. Product Introduction:

RTTS safety joint is a security tool, packer stuck available RTTS safety joint to help propose the tubing string above the safety joint, this security the connector disengaged First to string exert a pull, pull off pull sets. However, this can not be safety joint release, but also up and down movement of the column, and holding torque to loose safety joint.

2. Technical Parameters:

| SPECIFICATION | 5″ | 5 1/2″ | 7″ | 9 5/8″ |

| OD | 93.5mm | 103mm | 127mm | 155.5mm |

| ID | 45mm | 50.5mm | 57mm | 79mm |

| LENGTH | 1186mm | 1141mm | 1263mm | 1196mm |

| TENSILE | 89±4.5KN | 88.9±4.5KN | 111±10 KN | 177.8±10 KN |

| WORKING PRESSURE | 70MPa | 70MPa | 70MPa | 70MPa |

| WORKING TEMPERATURE | -29℃~+177℃ | -29℃~+177℃ | -29℃~+177℃ | -29℃~+177℃ |

| TENSILE STRENGTH | 623KN | 691KN | 1156.4 KN | 1636.8KN |

| BURST STRENGTH | 130MPa | 120MPa | 100 MPa | 117 MPa |

| COLLAPSE RESISTANCE | 120MPa | 110MPa | 93MPa | 108MPa |

| CONNECTION TYPE | 2 7/8"CAS.B×P | 2 7/8"CAS.B×P | 3 7/8"CAS.B×P | 3 7/8"CAS.B×P |

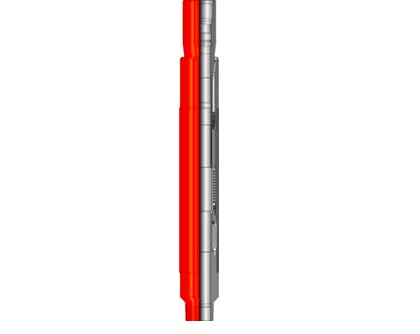

1. Product Introduction:

Products: Full Bore select the test valve is my company according to the higher demands of the new geological and wellbore condition of the formation testing technology, the latest development on the basis of the voltage-controlled test valve (LPR-N TEST VALVE) developed full bore annulus pressure operation, a new generation of test valve can be locked open wells. It overcomes the shortcomings and deficiencies of the prior full bore formation testing tool, have the nature of innovation in the structure and performance, not only to test the general downhole conditions easier, safe, reliable, accurate, and more adapted to the high temperature, high pressure , deep well, gas well formation test, not only of the wellbore conditions, but also broaden the formation testing and downhole operation (such as perforating, acidizing, fracturing, induced flow discharge cement squeeze job, etc.) compatibility.

2. Technical Parameters:

| SPECIFICATION | 5″ |

| OD | 127.5mm |

| ID | 57mm |

| LENGTH | 7384mm |

| WORKING PRESSURE | 105MPa |

| BALL VALVE OPENING DIFFERENTIAL | 35MPa |

| BALL VALVE WORKING PRESSURE | 70MPa |

| WORKING TEMPERATURE | -29℃~+177℃ |

| TENSILE STRENGTH | 1947KN |

| BURST STRENGTH | 140MPa |

| COLLAPSE RESISTANCE | 130MPa |

| TORQUE STRENGTH | 61KN•m |

| CONNECTION TYPE | 3 7/8″CAS.BXP |

RTTS CIRCULATING VALVE

1. Product Introduction:

RTTS circulating valve is an open or Closed locking state type tool, It can be used as a circulating valve, but also as a bypass valve. This cycle valve is always used with multifunction packer.

2. Technical Parameters:

| SPECIFICATION | 5″ | 5 1/2″ | 7″ | 9 5/8″ |

| O.D | 91.5mm | 106mm | 117.5mm | 155.5mm |

| I.D | 45mm | 50.5mm | 60mm | 76.2mm |

| LENGTH | 949mm | 903mm | 927mm | 1089mm |

| WORKING PRESSURE | 70MPa | 70MPa | 70MPa | 70MPa |

| WORKING TEMPERATURE | -29℃~+177℃ | -29℃~+177℃ | -29℃~+177℃ | -29℃~+177℃ |

| TENSILE STRENGTH | 949KN | 871KN | 1567KN | 2275.3KN |

| BURST STRENGTH | 140MPa | 91MPa | 159MPa | 115MPa |

| COLLAPSE RESISTANCE | 130MPa | 86MPa | 148MPa | 108MPa |

| OPEN AREA OF CIRCULATION PORT | 2700mm | 3478mm | 1700mm | 2550mm |

| TORQUE STRENGTH | 23KN•m | 24KN•m | 42KN•m | 95KN•m |

| CONNECTION TYPE | 2 7/8″CAS.B×P | 2 7/8″CAS.B×P | 2 7/8″CAS.B×P | 3 7/8″CAS.B×P |

SLEEVE TYPE DRAIN VALVE

1. Product Introduction:

This valve is a the pipe string test after for lofting tools, go down before lofting pressure relief sleeve hole by two sets of O-ring seals, pressure relief sleeve and pressure relief screw Apply two screws mix live, to go down during the operation, so that the pressure relief sleeve will not loose, after the test, connected to the stakeout clamp, turn the pressure relief screw sets, the pressure relief sleeve to the upper end of the movement, beware of the holes on the shaft body with pressure relief slip put on the stakeout hole is on, you can achieve a stakeout.

2. Technical Parameters:

| SPECIFICATION | 3 7/8″ | 5″ |

| O.D | 99mm | 127.5mm |

| I.D | 45mm | 57mm |

| LENGTH | 1159mm | 1159mm |

| WORKING PRESSURE | 70MPa | 105MPa |

| WORKING TEMPERATURE | -29℃~+177℃ | -29℃~+177℃ |

| TENSILE STRENGTH | 844KN | 1800KN |

| BURST STRENGTH | 140MPa | 150MPa |

| COLLAPSE RESISTANCE | 130MPa | 140MPa |

| TORQUE STRENGTH | 14.5KN•m | 30KN•m |

| / CONNECTION TYPE | 2 7/8″CAS & 2 7/8″EUE | 3 7/8″CAS & 3 1/2″IF |

1. Product Introduction:

This valve is used within the cased well to tubing pressure test operation of full bore pressure test valve, this tool in a formation testing prior to the valve above the tubing can be performed repeatedly seal pressure test. The tool in the well test, the main valve should be open in the well. In downhole operation, the valve is opened after will not again be closed, the oil pipe pressure test after the end, from the annulus pressure operation, allowing the tool baffle valve opening, also can be closed at the same time pressure control valve testing.

2. Technical Parameters:

| SPECIFICATION | 5″ |

| O.D | 127.5mm |

| I.D | 57mm |

| LENGTH | 1334mm |

| WORKING PRESSURE | 105MPa |

| WORKING TEMPERATURE | -29℃~+177℃ |

| TENSILE STRENGTH | 3550KN |

| BURST STRENGTH | 152MPa |

| COLLAPSE RESISTANCE | 141MPa |

| SHEAR FORCE VALUE | 3.5±0.2MPa/只 |

| SHEAR PIN TOTAL QUANTITY | 12只 |

| TORQUE STRENGTH | 30KN•m |

| CONNECTION TYPE | 3 7/8″CAS.BXP |

RH Single Hydraulic-Set Retrievable Packer

1. Product Introduction:

RH type hydraulic recyclable type casing packer is a recyclable hydraulic sitting seal type well completion production packer, widely used in oilfield development and production, it can be used individually, as well completion production packer; can also be used as a plurality, straddle packer water plugging or layering production packer. The packer seal, releasing, releasing operation is safe and convenient construction, high success rate, sit after the good sealing effect, long time of packer. At the same time, the upper part of the design of the hydraulic anchor packer structure, can bear negative pressure difference of oil production and development, is the ideal of a recyclable type completion packer.

2. Technical Parameters:

| SPECIFICATION | 7″ |

| O.D | 147.6mm |

| I.D | 60mm |

| LENGTH | 1392mm |

| WORKING PRESSURE | 52MPa |

| WORKING TEMPERATURE | -29℃~+177℃ |

| TENSILE STRENGTH | 775.6KN |

| BURST STRENGTH | 64.3MPa |

| COLLAPSE RESISTANCE | 73MPa |

| SHEAR FORCE VALUE | 1.65±0.2MPa/只 |

| SHEAR PIN TOTAL QUANTITY | 8只 |

| UNSET TENSION | 105.2~145.1KN |

| /CONNECTION TYPE | 27/8″EUE.BXP |

Products

+Drilling Equipment

- Casing Scraper

- balck rhino Non rotating Casing Scrappe

- RazRdillo Casing Scraper

- multiple activation autolock bypass tools

- Non-rotating wellbore casing scraper

- Wellbore Cleaning up tools

- Drill Pipe

- Downhole Motor

- KINGWELL Stabilizer-sleeve type

- Deflecting tools and mill tools

- drill bits

- Cross Coupling Cable Protector

- KINGWELL Underreamer

- Reammate Underreamer

- mill shose

- KINGWELL Raiseboring drill pipes

- Stabilizer

- future drill tools

- RGS Remote Gauge Stabilizer

- Shock Tools

- Casing and Pipe cutting equipment

- HORNET Series Drilling Tools

- Hydraulic Oscillator

- Hydraulic Thruster

- Drill Bit

- Jar Intensifier Type YJQ

- Overshot

- Full opening safety valve

- Top Drive Drilling Tools

- Hole Opener

- Drill Hydroscillator

- Lubricated Fishing Bumper Sub Type BXJ

- Drilling Jar

- Continuous Circulating Valve

- Inside Blowout Control Tools

- Multi-cycle Circulating tools

- Hydraulic Jar Type YSJ

- Drilling Accelerator Type ZJQ

- Fishing Bumper Sub Type KXJ

- Model DJQ Cable Jar

- Model ZTX Highly-Efficient Vibration Resi

- Super Fishing Jar Type CSJ

- Surface Bumper Jar Type DJ

- Surface Bumper Jar Type DX

- Two-action Drill Accelerator Type SZJQ

- Fishing Spear

- Junk Basket

- Wear Preventive Subs

- Kelly

- Heavy Weight Drill Pipe

- Drill Collar

- Magnetic Fishing Tool

- Die Collar

- Casing Scraper

- Shock Absorber

- Pup Joint

- Subs

+Rig Accessories

- KWDWS Water Cooling Eddy Current Brakes

- BOP

- Christmas Tree

- An Overview of OCTG Piping Inspection Met

- Casing and tubing

- Wire-wrapped Screen

- ASTM A53 GRADE B SEAMLESS

- flange

- EN 10217 Welded steel pipe

- Oil Country Tubular Goods (OCTG)

- ASTM A333 Grade1 Carbon Steel Pipe

- Coiled Tubing

- High Pressure Fluid Control Products

- Coupling

- API 5CT Hot Rolled Tubing Pup Joint

- Ram Type and Annular Type Blowout Prevent

- Solids Control System

- Crown Block

- F-1600HL Mud Pump

- Coiled Tubing BOP

- drilling line

- Kill Manifold and Choke Manifold

- F-2200HL Mud Pump

- Ironroughneck

- Hydraulic Disc Brake System

- Mud Hopper and Mud mixing pump

- Gate Valve

- Top Drive

- OCTG

- Butterfly Valve

- Globe Valve

- Ball Valve

- Plug Valve

- Choke Valve

- Check Valve

- Casing Hanger and Tubing Hanger

- Tubing Spool and Casing Spool

- Slip

- Tong

- Elevator

- Tubing Head

- Casing Head

- Drawworks

- High and Low Pressure Pipe Manifold

- Forgings for Flange/Valve/Shaft/Gear

- Forging for Downhole Tools

- Pipe Mould

- Die Steel/Tool Steel

- Mandrel Bar

- Rolling Mill Roll

- Corrugated roll

- Travelling Block and Hook

- Rig Swivel

- Drilling Rig Mast

- Rotary Table

- Mud Pump

- Vacuum Degasser

- Other Solid Control Equipment

- Shaker Screen

- Submersible Slurry Pump

- Shear Pump

- Mud Agitator

- Centrifugal Pump

- Decanter Centrifuge

- Desilter

- Desander

- Mud Cleaner

- Linear Motion Shale Shaker

+APR Drill Stem Testing Tools

- Rupture Disk (RD) Sampler

- Slip Joint

- Hydraulic Jar

- Shock Absorber

- Gauge Carrier

- Drain Valve

- OMNI Valve

- LPR-N Valve

- Safety Valve

- Safety Joint

- Circulating Valve

- RTTS Packer

- Super Safety Valve/Subsea Safety Valves (

- Hydro Trip Pressure Sub

- Surface Well Testing system

- APR Pressure-controlled Formation Tester

- Full-bore Compensating Pipe

- Retrievable Service Packers

- Fullbore DST string

- DST TOOLS specification

- Subsurface Control Valve (SSC) Storm Vavl

- Champ v Packer

- Storm Valve

- Tester Valve